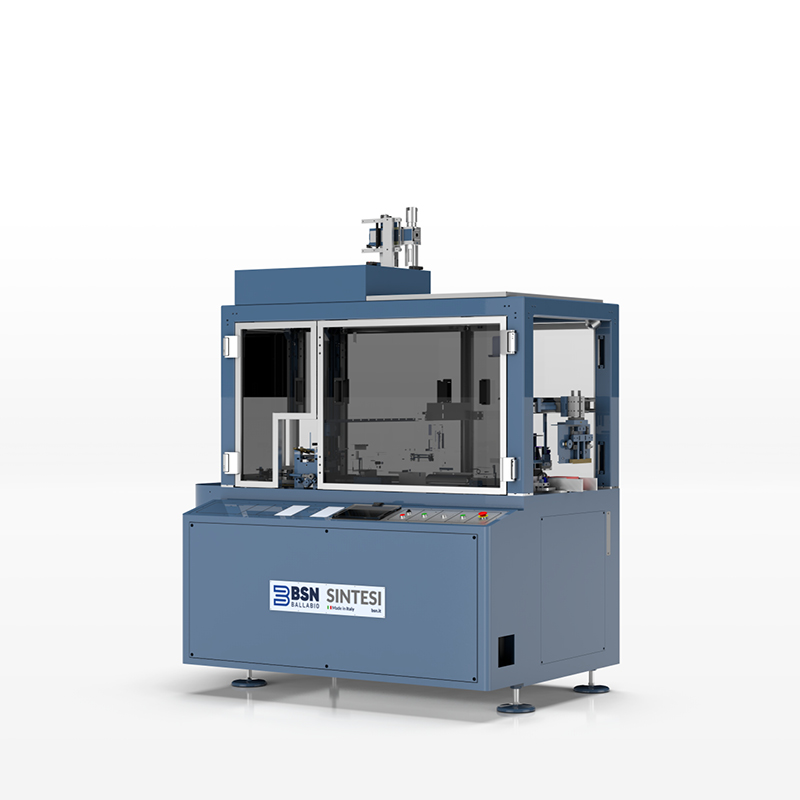

SINTESI has been designed in order to meet a large production request. The machine frame, which is completely made of steel, gives stability to the entire structure. The accuracy and reliability of its movement are guaranteed by hardened and rectified mechanical cams. Each boxing phase is controlled by sensors and photocells that stop production in case any even minimum anomaly is detected. A touch screen display can be used to interact with the machine, informing the operator about all Inputs and Outputs of components, thus facilitating both the production process and the production preparation and setting process.

The electrical equipment of SINTESI is top quality. An OMRON frequency controller is able to adjust the speed of the printing motor, so as to manage production, adapting it to the speed of the loading machine.

Sintesi is suitable for packing and closing 12-16-20-calibre cartridges (25 pieces) with heights of 65/67/70/76 mm.

Suitable for loading steel, felt wad.

Regular maintenance has been simplified thanks to a centralised lubrication system, thus reducing machine stop times and, consequently, costs. In addition, this system guarantees a uniform distribution of the lubricant, thus reducing the wear of mechanical parts. All motors are controlled by inverters in order to improve management and the product accuracy. Electrical pneumatic components: OMRON-FESTO-SIEMENS-BALLUFF- KEYENCE Mechanical components: ROSSI-NSK-MAYER-SKF.

It can be connected to the following loading machines: Kameleon with a maximum hourly production of 7,500 pieces per hour. Extrema with a maximum hourly production of 15000 pieces per hour.

15000 pcs/h

Length: 2100 mm / PDepth: 1400 mm

Height 1700 mm

1500 Kg